- Rice Mill[6]

- Boilers[6]

- Other Metal Processing Machinery[6]

- Machinery Stock[1]

- Oil Pressers[6]

- Pipe Fittings[6]

- Valves[6]

- Flanges[6]

- Mixed Spices & Seasonings[6]

- Monosodium Glutamate[6]

- Food Additives[1]

- Aluminum Powder[4]

- Oxide[1]

- Other Aluminum[6]

- Refractory[2]

- Contact Person : Ms. Wei yoyo

- Company Name : Zhengzhou Bihe Trade Co., Ltd.

- Tel : 86-0371-15138973853

- Fax : 86-0371-68271757

- Address : Henan,zhengzhou,NO817 room futian square hanghaizhongzhou Road zhengzhou China

- Country/Region : China

- Zip : 475000

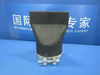

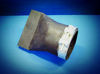

The slip on Duckbill Check Valves and Duckbill Valves

The slip on Duckbill Check Valves and Duckbill Valves:

Rubber check valve also known as: rubber sewage check valve, sewage rubber check valve, rubber check valve.

1) quality garantee 2) specific certificate3) good quality and competetive price

slip on Rubber duckbill valve size standards:1) mounting dimensions flange connection to the GB, which is the earliest design rubber duckbill valve by Lee Tongwen engineers, in order to want to match with the national standards, the provisions of the 800 caliber rubber duckbill valve flange standard mixed GB ten kilograms bolt hole center distance and flange outside diameter, the diameter more than 800 (inclusive), with reference to GB 6 kg bolt hole center distance and flange outer diameter.

2) installation dimensions in Jiangsu the Blue valve, Nanjing water beauty of its own size, the size of different national standards, but there are likely to prevail in American Red valve or Spain screw.

Rubber Duckbill Valve Directions:

1) Open pressure: 0.003MPa, equivalent to a basin of water.Under normal circumstances, the duckbill valve can normally 3 meters in the underwater work, but this height is, counting from the bottom of the duckbill valve, plus special apparatus, can reach 10 meters underwater.

2) Service Life: the design life of two years, but in general, at room temperature, and the climate is bad, you can use five years, even as long as 10 years, but the proposed one-for five years to prevent aging.

3) The head loss of about 5% to 8%.

Rubber duckbill valve detailed data:

Matdhing Pipeline DN | Valve Step(A) | Pipeline Touching(B>) |

1/2"~3/4" | 15 | 15 |

1"~1-1/4" | 20 | 20 |

1-1/2"~2-1/2" | 25 | 25 |

3" | 40 | 40 |

4" | 50 | 50 |

6" | 50 | 50 |

8" | 50 | 50 |

10" | 50 | 50 |

12"~14" | 100 | 100 |

16"~20" | 150 | 150 |

24"~36" | 200 | 200 |

42" | 250 | 250 |

48"~60" | 300 | 300 |

72" | 400 | 400 |

The advantages are specially marked in comparison with traditional flap valve:

1. Open and close automatically in security and reliability according to hydraulic difference without noise and in no need of operator and maintenance;

2. Positive start has little water resistance and start –up pressure and the flow can be adjusted naturally according to hydraulic pressure.

3. Reserve cut-off has good seal without leakage to prevent from flowing backwards. The back pressure is higher and the effect is barrier;

4. Anticorrosion, aging resistance, deformation resistance, strong adapt-ability and long use life;

5. Wide size scope, nominal diameter of DN50-DN3000.

Applications cope of rubber check valve:

1.Excellent performance ad wide application scope

2.Applicable for sewage system

3.Applicable for discharge system

4.Applicable for dyke discharge

5.Applicable for the drainage of airport and freeway

6.Applicable for sewer discharge

7.Applicable for swage lagoon dis-charge

8.Smell separation

The slip on Duckbill Check Valves and Duckbill Valves